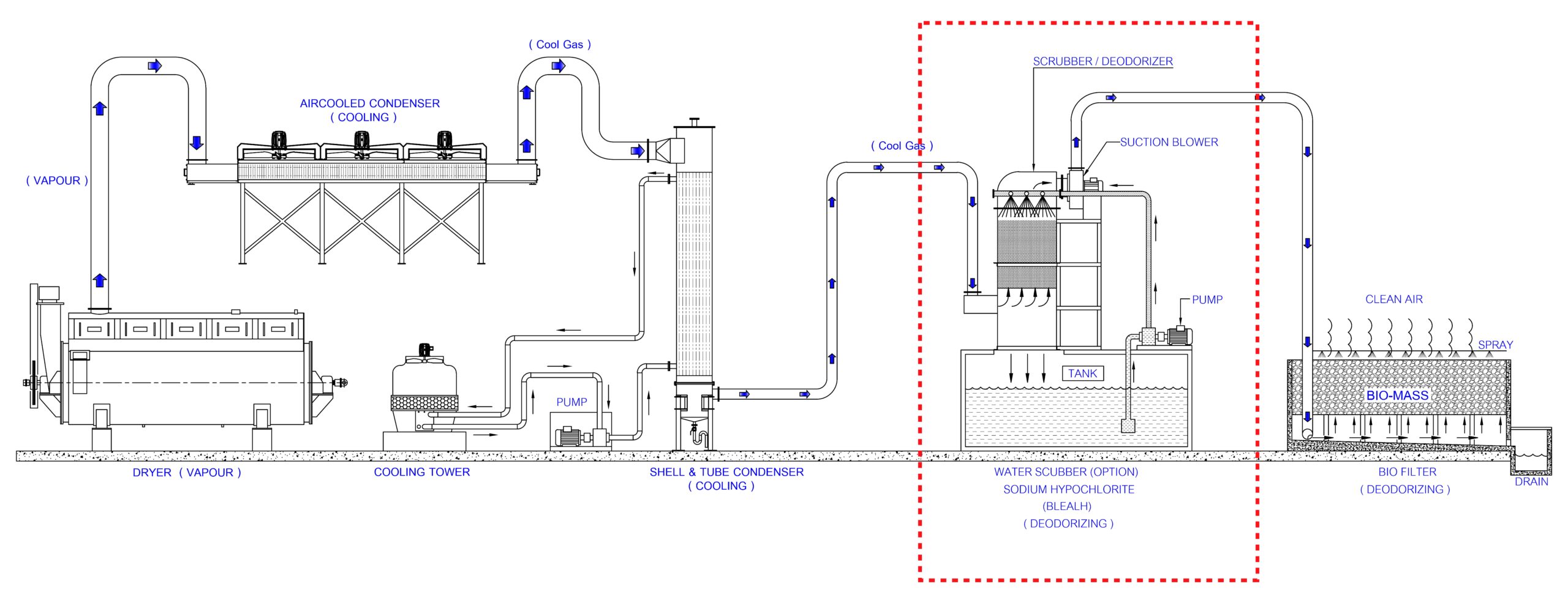

The ASTW water scrubber uses a large volume of water to wash away the remaining smell in the waste vapour and rest gas.

The amount of water needed will vary with the size of the plant and the amount of smell removal performed during previous steps as described above.

If a high volume of water from sea or river is available, it is possible to use a water scrubber as the only condensation and smell removal method, volume about 45 m3 water per one ton of plant capacity.

The cooling water heats up about 10 degrees and goes back to the sea or river without causing pollution.

If the scrubber is used only for smell removal in rest gas that has already been cooled, the water can run in a closed system from a holding tank.

However, in most cases a combination of methods must be used.

Chemical additives:

It is possible to continuously mix a small volume of sodiumhypochlorite (normalclothing bleach)

into the closed system scrubber to remove the smell from the rest gas.

This simple method is especially useful when the air from the building and “point suction”

from each individual machine is to be deodorised but does not need to be cooled down.

Proven success across 300+ installations worldwide. Discover how ASTW’s turnkey fishmeal and rendering solutions have helped global clients achieve superior efficiency, reduce operational costs, and exceed environmental compliance standards.

ASTW delivered a turnkey fishmeal plant in eastern Thailand, designed for lean fish and marine by-products. The project included full installation, energy-saving systems, and odor control to comply with local environmental regulations. Key Equipment 3-Phase Decanter LTR Disc Dryer Preheater Twin Screw Press WHE

Proven success across 300+ installations worldwide. Discover how ASTW’s turnkey fishmeal and rendering solutions have helped global clients achieve superior efficiency, reduce operational costs, and exceed environmental compliance standards.

Our fishmeal and rendering plants process various raw materials including fish waste and by-products, poultry offal and feathers, beef and pork by-products, mixed animal waste, and seafood processing waste. Each plant is customized for specific material types to ensure optimal processing efficiency and product quality.

Yes, ASTW delivers complete turnkey solutions including engineering design, equipment manufacturing, worldwide shipping, on-site installation, system commissioning, operator training, and ongoing technical support. Our 40+ certified technicians handle projects from concept to full operation across 36+ countries.

We provide comprehensive 24-month equipment warranty, 5-year major component guarantee, lifetime technical support, global spare parts availability, preventive maintenance programs, and 24/7 emergency service. Our service network ensures minimal downtime and maximum plant performance.

Absolutely. Our plants include advanced odor control systems (biofilters, scrubbers, thermal oxidizers), environmental monitoring equipment, waste heat recovery systems, and compliance with international environmental standards including EU, EPA, and local regulations worldwide.

Emergency spare parts are available within 24-48 hours for critical components through our global distribution network. Standard parts ship within 5-7 business days. We maintain strategic inventory locations in Asia, Europe, and Americas to ensure rapid delivery worldwide.

Our plants range from 50 tons/day for smaller operations to 600+ tons/day for large-scale industrial facilities. We design custom solutions based on your raw material volume, product requirements, site conditions, and future expansion plans.