A Fish Meal Plant is an industrial facility specifically designed to process fish raw materials (e.g., whole fish, fish offal, or fish processing by-products) into fish meal and fish oil through high-temperature cooking, pressing, drying, and other processes.

Its core function is to separate proteins, fats, and moisture from fish via physical and chemical treatments, producing highvalue animal feed and industrial raw materials while ensuring efficient resource utilization and waste reduction.

A fishmeal plant converts raw materials, which would typically be discarded, into two main high-value products:

A Fish Meal Plant is an industrial facility specifically designed to process fish raw materials (e.g., whole fish, fish offal, or fish processing by-products) into fish meal and fish oil through high-temperature cooking, pressing, drying, and other processes.

Its core function is to separate proteins, fats, and moisture from fish via physical and chemical treatments, producing highvalue animal feed and industrial raw materials while ensuring efficient resource utilization and waste reduction.

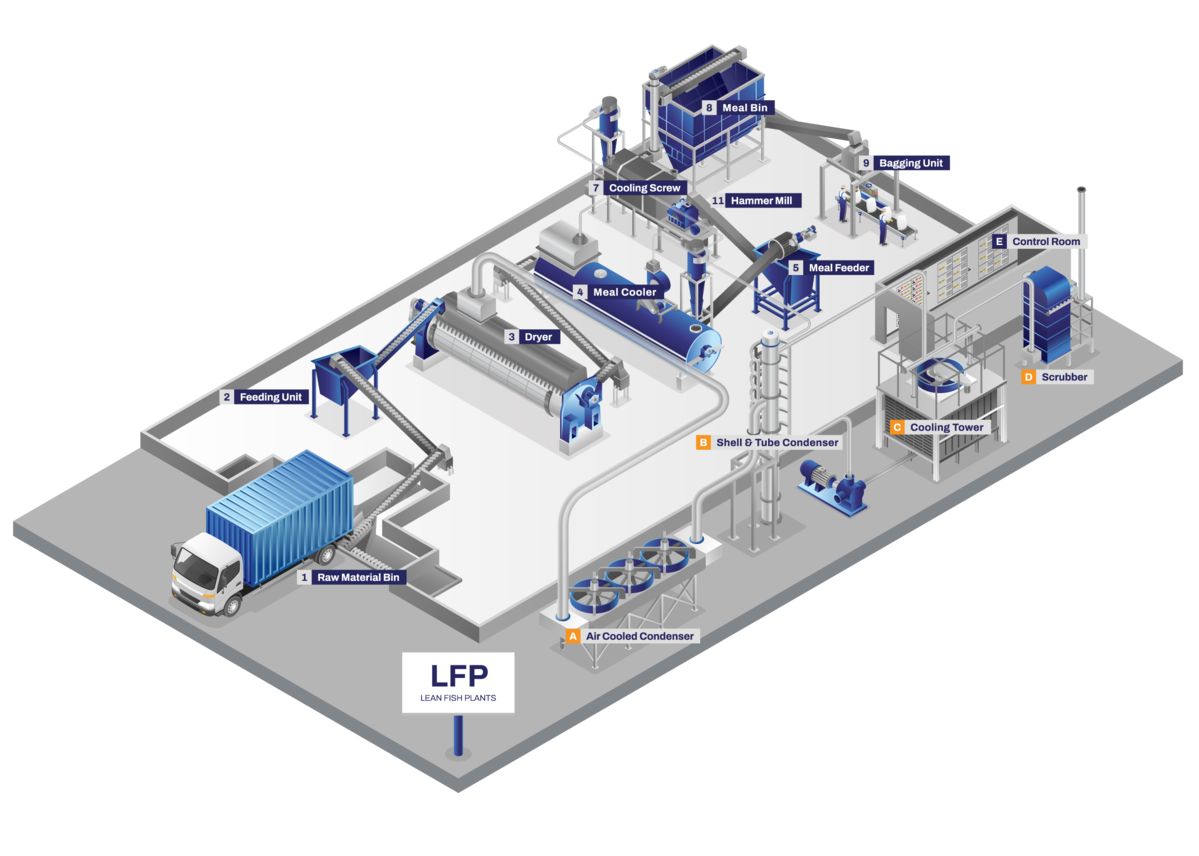

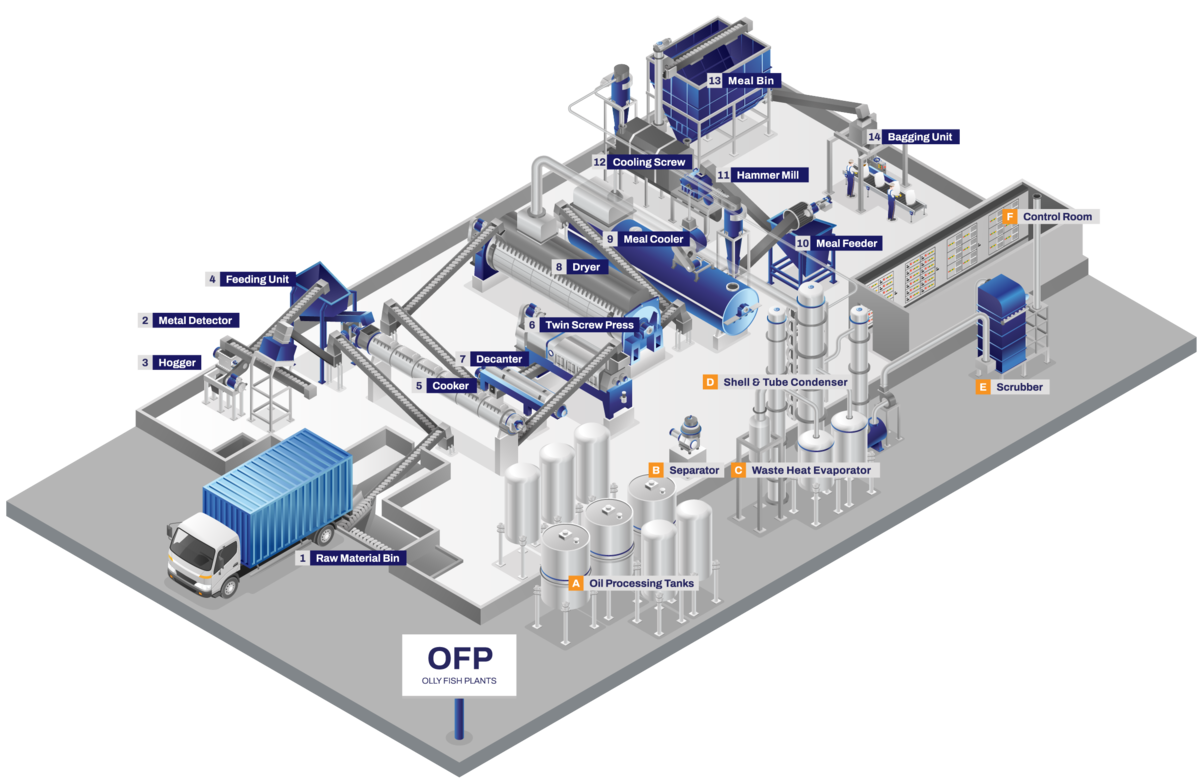

ASTW invented the LFP – Lean Fish Plant – for Asian operations in1986 and have improved the technology ever since. OFP – Oily Fish Plants have been developed and improved for operation indifferent climatic zones and different species of fish. Our concept is simplicity and reliability.

A Lean Fish Plant (LFP) is a type of industrial facility specifically designed to produce fish meal from fish species and fish waste that have a low oil (lipid) content, typically defined as less than 3% oil.

It’s a specialized rendering plant in the fish processing industry, focusing primarily on maximizing protein recovery rather than oil extraction. Process: The LFP technology is characterized by a simpler design compared to plants for oily fish, primarily using a Rotating Disc Dryer to remove moisture and create the meal. Oil extraction equipment (like presses, decanters, and separators) is typically not necessary due to the low-fat content.

Scalability: The LFP plants can be extended to become Oily Fish Plants (OFP) by adding the necessary cooking, pressing, and separation equipment if a company decides to process higher-oil content materials later.

A Oily Fish Plant (OFP) is a type of industrial facility specifically designed to produce for fish and fish waste with more than 3% oil content. Produces high quality fishmeal and fish oil.

The OFP – Oily Fish Plant uses the same components as the LFP – Lean Fish Plant but with addition of a cooker, twin screw press, solid/liquid decanter separator, oil separator, plus pumps and tanks.

The plants are a modern design that will operate continuously for years and provides easy operation, low energy consumption, low maintenance and long life time. ASTW also provides excellent after sale service and carry a supply of spare parts in stock. All designs are based on Stord Norway technology. A Waste Heat Evaporator (WHE) can be included for plants larger than OFP 55 to save 40% steam.

Proven success across 300+ installations worldwide. Discover how ASTW’s turnkey fishmeal and rendering solutions have helped global clients achieve superior efficiency, reduce operational costs, and exceed environmental compliance standards.

ASTW delivered a turnkey fishmeal plant in eastern Thailand, designed for lean fish and marine by-products. The project included full installation, energy-saving systems, and odor control to comply with local environmental regulations. Key Equipment 3-Phase Decanter LTR Disc Dryer Preheater Twin Screw Press WHE

Proven success across 300+ installations worldwide. Discover how ASTW’s turnkey fishmeal and rendering solutions have helped global clients achieve superior efficiency, reduce operational costs, and exceed environmental compliance standards.

Our fishmeal and rendering plants process various raw materials including fish waste and by-products, poultry offal and feathers, beef and pork by-products, mixed animal waste, and seafood processing waste. Each plant is customized for specific material types to ensure optimal processing efficiency and product quality.

Yes, ASTW delivers complete turnkey solutions including engineering design, equipment manufacturing, worldwide shipping, on-site installation, system commissioning, operator training, and ongoing technical support. Our 40+ certified technicians handle projects from concept to full operation across 36+ countries.

We provide comprehensive 24-month equipment warranty, 5-year major component guarantee, lifetime technical support, global spare parts availability, preventive maintenance programs, and 24/7 emergency service. Our service network ensures minimal downtime and maximum plant performance.

Absolutely. Our plants include advanced odor control systems (biofilters, scrubbers, thermal oxidizers), environmental monitoring equipment, waste heat recovery systems, and compliance with international environmental standards including EU, EPA, and local regulations worldwide.

Emergency spare parts are available within 24-48 hours for critical components through our global distribution network. Standard parts ship within 5-7 business days. We maintain strategic inventory locations in Asia, Europe, and Americas to ensure rapid delivery worldwide.

Our plants range from 50 tons/day for smaller operations to 600+ tons/day for large-scale industrial facilities. We design custom solutions based on your raw material volume, product requirements, site conditions, and future expansion plans.