with World-Class Components

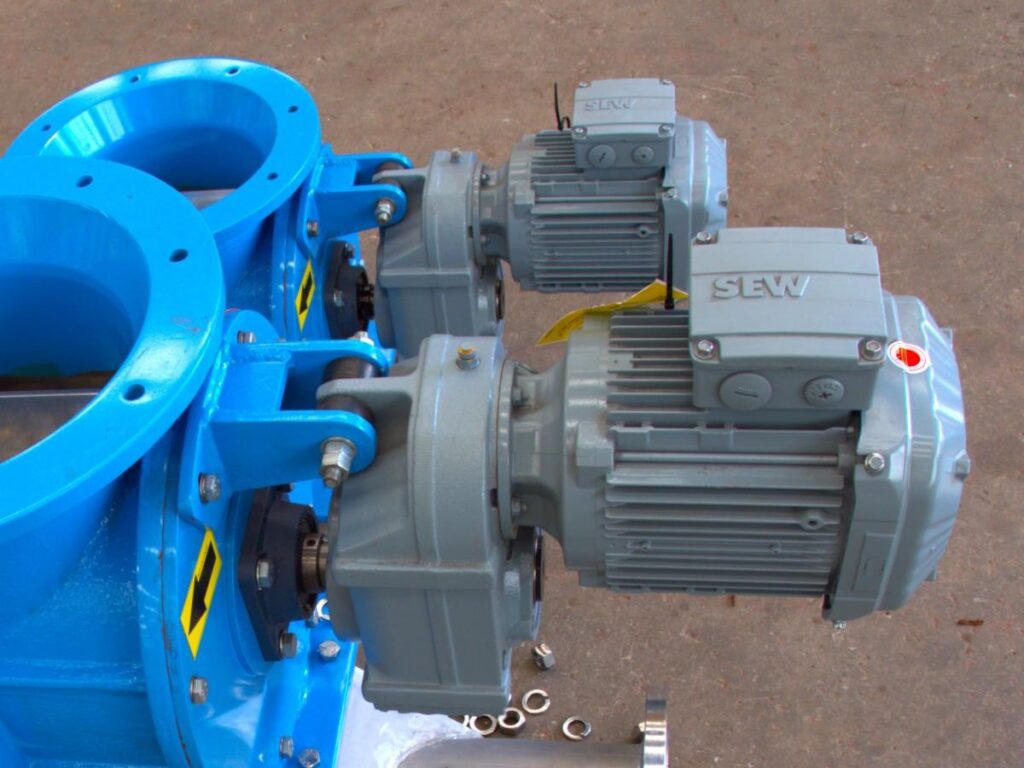

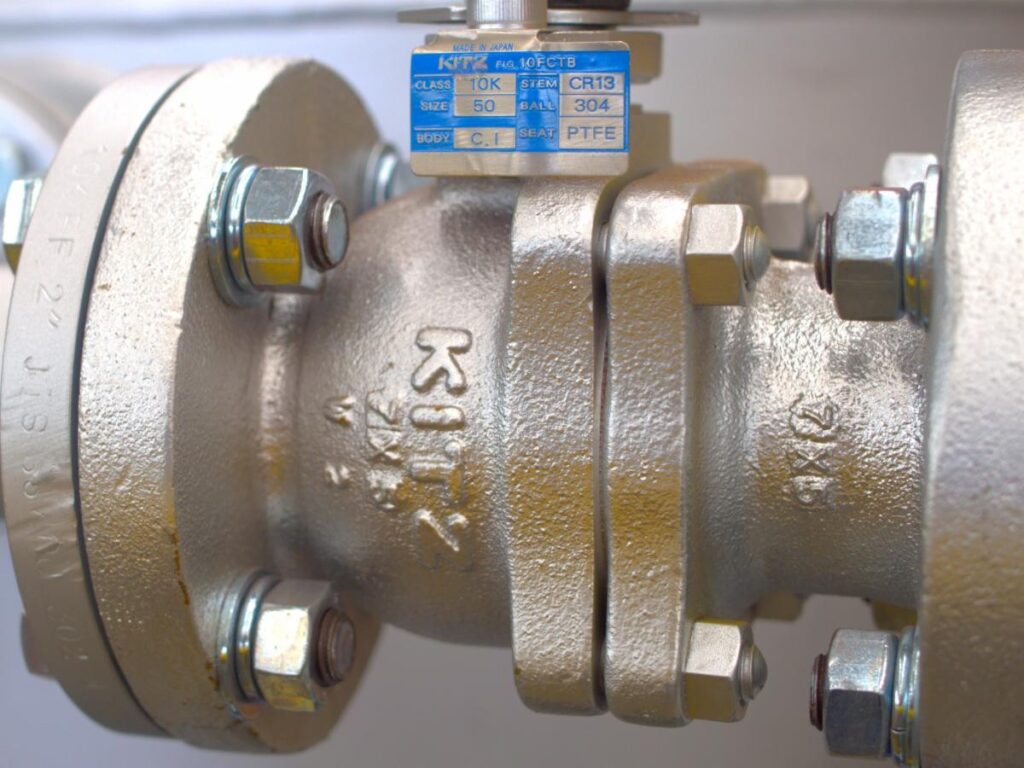

“That’s why we source only the finest materials from the world’s leading manufacturers.”

At A & S Thai Works, we believe that superior performance starts with superior materials. While others may cut costs with inferior components, we invest in premium materials that ensure decades of reliable operation, even under the most challenging conditions.

Our Example Premium Material Standards

MIG and FCAW Welding: We use only the most advanced welding techniques, considered the gold standard for industrial equipment manufacturing.

Our drying systems meet the highest international standards for safety and performance, resulting in many dryers still fully operational after 20 years.

Manufacturing Timeline Example: Our OFP 90 (Oily Fish Plant with 90-100 ton daily capacity) requires approximately 7-8 months of careful manufacturing. This timeline reflects our commitment to precision–every component is thoroughly tested and quality-checked before assembly.