A meat and bone rendering plant is an industrial facility that specializes in processing “by-products” from meat production. This includes non-edible meat scraps, bones, fat, offal, and whole animal carcasses left over from slaughterhouses, butcher shops, restaurants, and farms.

These plants use a process called “rendering,” where these raw materials are cooked at high temperatures to kill pathogens, reduce moisture, and separate the fat from the protein and minerals.

Rendering is a cornerstone of sustainability and public health in the animal agriculture industry.

ASTW There are two main processing methods and 2 addition process available

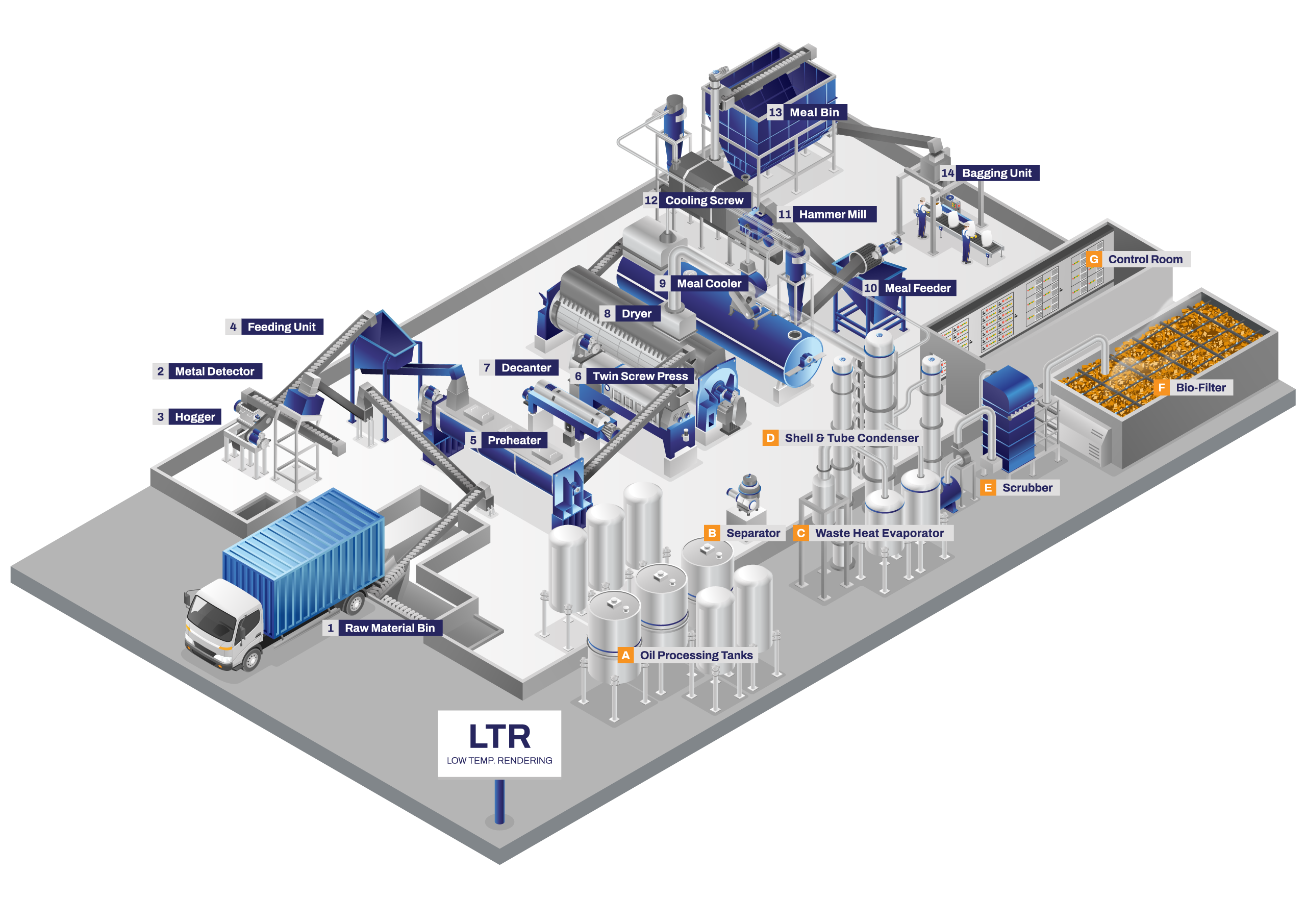

LTR = Low Temperature Rendering

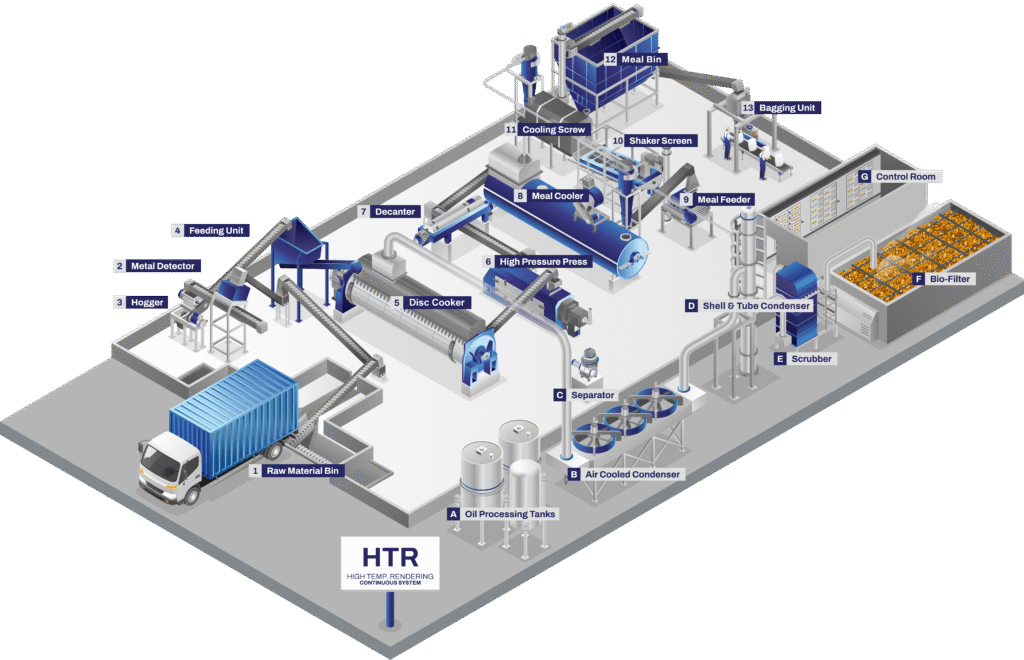

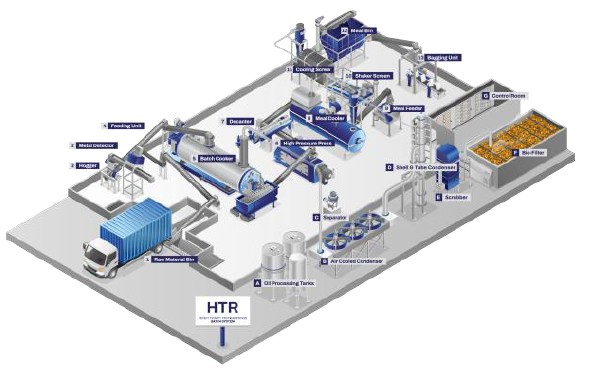

HTR (Continuous System) = High Temperature Rendering Plant

HTR (Batch System) = High Temperature Rendering Batch System

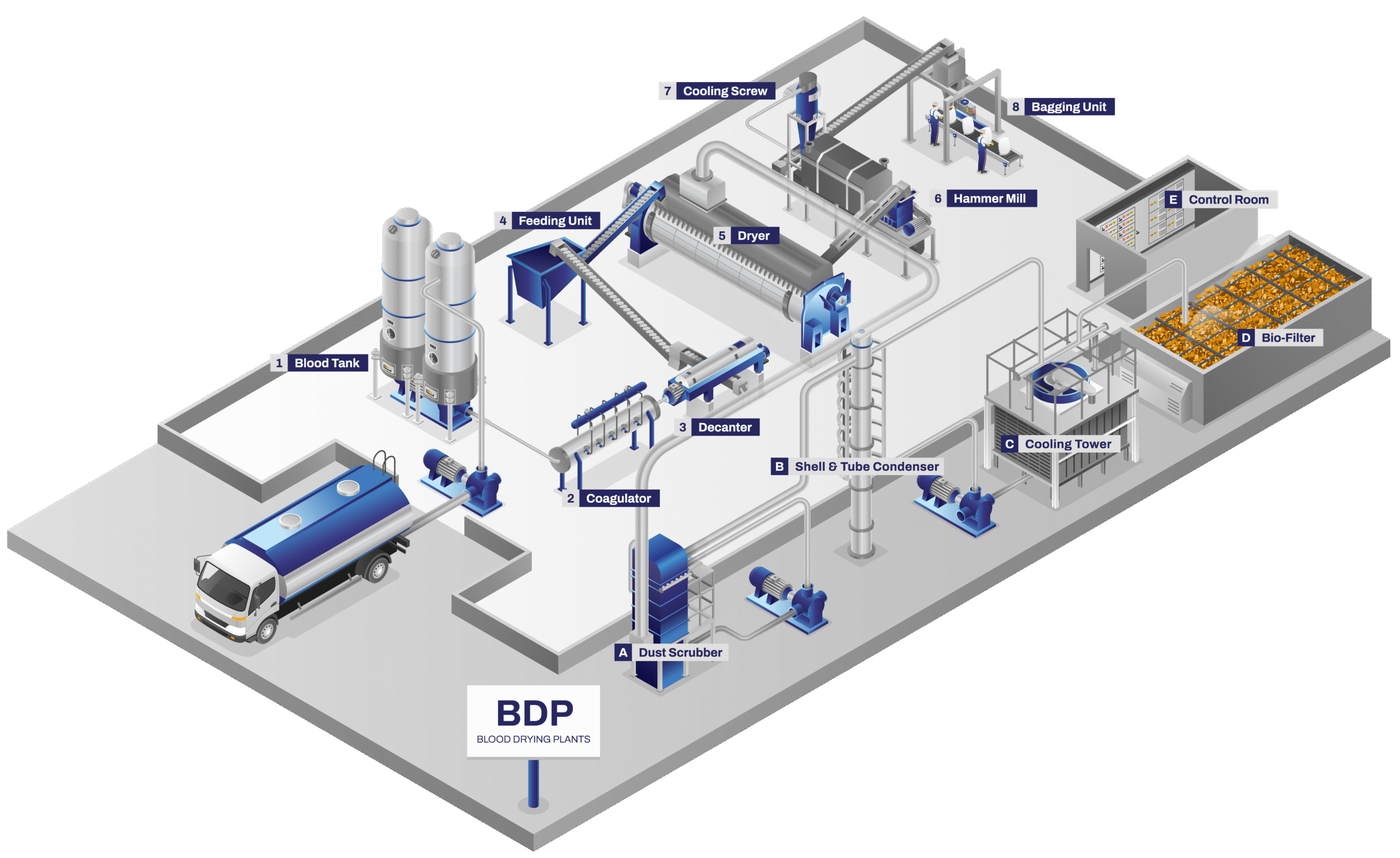

BDP = Blood Drying Plant

Low Temperature Rendering plants – LTR: for continuous processing of by-products such as bovine (beef), ovine (sheep) or chicken into high quality meat and bone meal and tallow.

The material is scanned for steel scrap in a metal detector, pre-breaker and fine pre breaker the material into small pieces about 25mm. The material is then cooked in a continuous pre-heater/cooker at temp. 95 ºC. The cooked material is pressed in a slow rotating twin crew press to separate press cake and press water which is separated to stick water and tallow in a 3- phase decanter and purifier separator. The solid are dried to meat and bone meal in a disc dryer and tallow is purified (polished), and can be further vacuum dried to remove all traces of water. The meal is cooled and ground in a hammer mill for storage. The greatest advantage of the gentle Low Temp Rendering process is that the chicken meal

and oil is of high quality if fresh raw material.

Main advantages:

The LTR plant produces a quality meat and bone meal and tallow and allows the use of WHE – waste heat evaporator that reduces the steam consumption by up to 50%, allowing steam consumption to be 550-600 kg steam per 1 ton raw material at about 65% moisture. All LTR components (except decanters and separators) are slow rotating machines and have low wear for long and reliable lifetime. Components are high quality like SEW gear boxes and Spirax steam equipment, sensors from VEGA and Endress Hauser. No steel material or parts are from low-cost countries.

A High Temperature Rendering (HTR) Plant is a facility that processes animal by-products (such as offal, bone, and fat) by applying high heat for a significant period of time to sterilize the material, evaporate moisture, and separate the fat from the protein solids.

It is one of the oldest and most traditional methods of rendering and is often categorized as a Dry Rendering process.

The material is scanned for steel scrap in a metal detector, cut in a pre-breaker to 50 mm and then in a fine-breaker to 16 mm. The material melts in the cooker and is cooked in a bath of hot tallow at high temperature 120- 130 degrees C. The cooker works like a large frying pan where the water is evaporated, and the greasy output (grax) is pressed in a high pressure press to extract most of the tallow. The hot tallow is clarified in a 2-phase decanter and separator/polisher. The press cake is cooled and ground in a hammer mill for storage as an animal feed component. Wool or hair in the material is partially hydrolysed due to the high frying temperature, and separated in the shaker screen before grinding to meal in the hammer mill.

Main advantages:

The advantage of the high temp process is that it is a simple process and that the cooker can be of relatively small size but with a high evaporation capacity up to 24 kg per m2 heating surface per hour.

The HTR process is somewhat simpler than the LTR process, but not as energy efficient.

The batch cooker has been used in the rendering industry since the 1940s. It is a simple steam heated machine with a jacketed cylinder and a mixing rotor that can process, cook and dry materials in “one batch”

Today batch cookers are used mainly for small, low cost rendering capacities, while continuous systems are being used for larger capacities. For feathers, the batch cooker is sometimes used together with a more efficient disc dryer and increase capacity about 30%.

Mixed meat and meat, bone and intestines (high temp drying) fry and dry the material in oil bath at 135 deg C, to be used with high pressure press

Mixed poultry offal = offal and feathers mixed together (hydrolyzing and drying) => meal for animal feed and tallow/chicken oil, with high pressure press

Feathers (hydrolyzing and drying) => feather meal for animal feed

Blood (cooking and drying of decanter cake) => blood meal for animal feed

Wool and hair from processing of sheep, hog (swine) (hydrolyzing and drying) => feed back into the rendering process

The batch cooker design has a heated shell with a steam jacket and a heated mixer rotor. There is an inlet chute and a bottom outlet, both with knife gate valves. The body is designed to withstand internal pressure up to 5 bar (operation 3 bar)

Continuous drying of fresh blood to blood meal.

Blood is a valuable, high protein (~ 80%) raw material, but with high water content and low meal yield, typically 13-15%.

Blood meal is sold to animal feed producers (feed mills), or mixed in with the meat and bone meal process.

Using a decanter and a disc drier, ASTW provides a cost-effective method for the production of blood meal.

The indirectly heated disc dryer gives a continuous drying process, specially designed to handle difficult and sticky materials

The Blood drying plant includes the following steps:

Proven success across 300+ installations worldwide. Discover how ASTW’s turnkey fishmeal and rendering solutions have helped global clients achieve superior efficiency, reduce operational costs, and exceed environmental compliance standards.

ASTW delivered a turnkey fishmeal plant in eastern Thailand, designed for lean fish and marine by-products. The project included full installation, energy-saving systems, and odor control to comply with local environmental regulations. Key Equipment 3-Phase Decanter LTR Disc Dryer Preheater Twin Screw Press WHE

Proven success across 300+ installations worldwide. Discover how ASTW’s turnkey fishmeal and rendering solutions have helped global clients achieve superior efficiency, reduce operational costs, and exceed environmental compliance standards.

Our fishmeal and rendering plants process various raw materials including fish waste and by-products, poultry offal and feathers, beef and pork by-products, mixed animal waste, and seafood processing waste. Each plant is customized for specific material types to ensure optimal processing efficiency and product quality.

Yes, ASTW delivers complete turnkey solutions including engineering design, equipment manufacturing, worldwide shipping, on-site installation, system commissioning, operator training, and ongoing technical support. Our 40+ certified technicians handle projects from concept to full operation across 36+ countries.

We provide comprehensive 24-month equipment warranty, 5-year major component guarantee, lifetime technical support, global spare parts availability, preventive maintenance programs, and 24/7 emergency service. Our service network ensures minimal downtime and maximum plant performance.

Absolutely. Our plants include advanced odor control systems (biofilters, scrubbers, thermal oxidizers), environmental monitoring equipment, waste heat recovery systems, and compliance with international environmental standards including EU, EPA, and local regulations worldwide.

Emergency spare parts are available within 24-48 hours for critical components through our global distribution network. Standard parts ship within 5-7 business days. We maintain strategic inventory locations in Asia, Europe, and Americas to ensure rapid delivery worldwide.

Our plants range from 50 tons/day for smaller operations to 600+ tons/day for large-scale industrial facilities. We design custom solutions based on your raw material volume, product requirements, site conditions, and future expansion plans.